Timber is one of the oldest building materials known.

It has been used in buildings in most parts of the world for thousands of years.

In low energy ages, timber was the natural material of choice

Timber is a light construction material with a high strength to weight ratio.

Standing timber: part of a living tree

Rough timber: part of a felled tree

Converted timber: sawn to various forms like beams, battens and planks, etc.

Dressed timber: sawn timber which has been placed and worked to the required condition.

Clear timber: timber free from defects.

Classification of trees

Endogenous: Grows inwards.

Grow in longitudinal fibrous mass like palm, cane, bamboo, banana, etc. Except bamboo unsuitable for engineering purpose.

Exogenous: Grow outwards.

Conifers: Evergreen trees yielding soft wood. Deodar, chir, fir, kail, etc. Distinct annual rings, straight fibers, light color, resinous and light weight.

Deciduous: Flat broad leaf trees yielding hard wood. Oak, teak, shishum, poplar and maple. Indistinct annual rings, non-resinous, dark in color and heavy weight

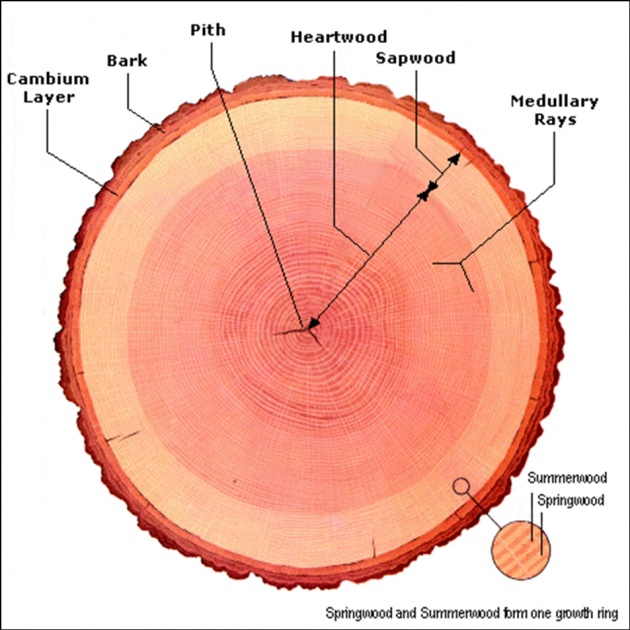

Structure of tree

Pith or Medula: innermost portion or core of tree.

Heart wood: inner annual rings surrounding pith.

Sap wood: outer annual rings that transmit sap from root to branches.

Cambium: thin layer below bark, not converted to sap wood not as yet.

Bark (outer & inner): outermost protective layer of cells and woody fibers that splits and peels off. It is the skin of the stem.

Annual rings: these consist of cellular tissues and woody fiber arranged in distinct circles or rings around the pith generally one in every year.

Medullary rays: thin horizontal veins from bark to pith to carry sap inwards. Only few are visible to naked eye and they hold the annual rings together.

Tree growth

Spring season

Salt and water solution sucked by the roots

Under sunlight absorbs CO2 from air

Viscous solution is called sap

Autumn season

Sap descends under the bark and leaves a thick layer

Sap layer transformed into wood as cambium layer

New layer added each year as annual ring

Sap carried through medullary rays from bark to interior

New wood on outside of tree

oldest wood on the inside

youngest wood on the outside

diameter largest at the base

one ring (layer) per growing season

Tree in forest grows toward light

trunk is straight

lower branches die

leaving small knots in wood

Bark protects wood from damage

the tree sheds bark each year

Characteristics of good timber

Obtained from heartwood area of tree and free from sap

Should have straight and close fibers

Dark uniform color with uniform texture

When struck, sonorous (loud & deep) ringing sound is produced

Narrow annular rings, closer the rings greater is the strength

Compact medullary rays

Sweet smell and a shining fresh cut surface

No clogging of saw teeth during sawing

Free from the defects like dead knots, shakes etc

Heavy weight

Bright and smooth surface when planed

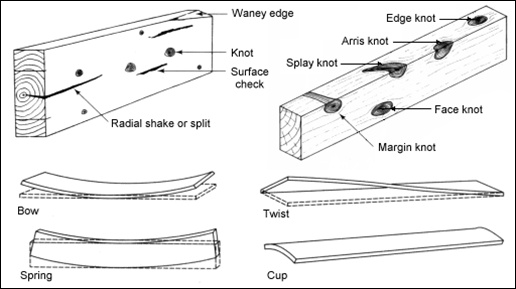

Defects in timber – during growth

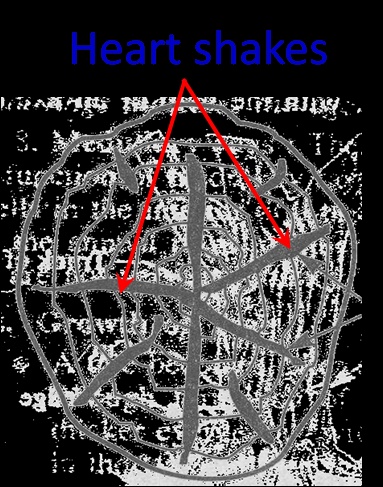

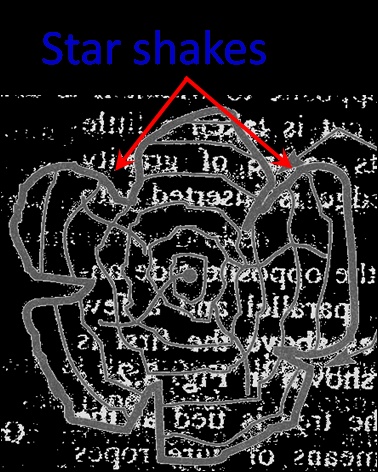

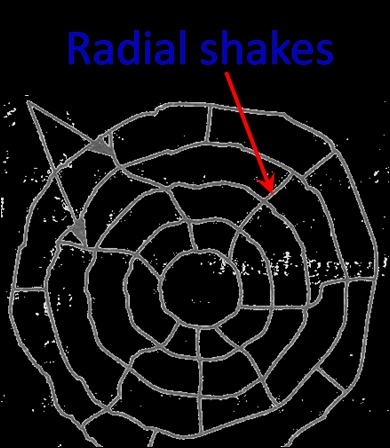

Shakes: separations between annual rings

Heart shake: radial splits in heartwood due to shrinkage

Star Shake: radial splits or cracks wider on surface and narrow inwards, due to severe heat and frost action

Cup shake: curved split among annual rings. Also called ring shake

Radial shake: similar to star shakes but are finer, irregular and numerous

Upsets: crushing of transverse fibers due to winds

Twisted fibers: wind turning the trunk and twisting fibers

Rind galls: growth of sapwood layer over wounds

Defects in timber - knots

Knots: root of small branches buried in mother branch annual rings. This modifies the tissues in elliptical or concentric circles . Knot disturbs the homogeneity , strength and workability of wood.

Dead or loose knot: separable

Live or sound knot: inseparable

Size based classification

Pin knot: under 12 mm

Small knot: 12 to 20 mm

Medium knot: 20 to 40 mm

Large knot: over 40 mm

Form based classification

Round knot

Spike knot

Quality based classification

Sound knot: hard and solid as surrounding wood

Decayed knot: contains advance decay, softer than surrounding wood

Encased knot: annual rings fail to grow into fibers of surrounding wood

Tight knot: a knot so securely fastened that it holds its position in finished product

Occurrence based classification

Single knot: wood fibers deflect around one knot

Cluster knot: wood fibers deflect around two or more knots as one unit

Branch knot: two or more knots radiating from one common center

Defects in timber – diseases and decay

Diseases

Dry rot: fungus turns timber to dry powder

Wet rot: decay due to alternate wetting and drying

Decay

Decay due to fungal and bacterial attack

Damage due to insects

Termites, white ants

Beetles: powder post beetles, long horn beetles, ambrosia beetle,

Carpenter ants

Damage due to rodents (mice, rats, squirrels, etc.)

Seasoning of timber

Seasoning: extraction of moist sap under controlled conditions (as nearly as possible at a uniform rate) from all parts of timber, and to leave inextricable moisture uniformly distributed throughout

Irregular drying causes irregular shrinkage leading to warping and shakes formation

Objectives:

To reduce the shrinkage and warping after placement in structure.

To increase strength, durability, and workability.

To reduce its tendency to split and decay.

To make the timber suitable for painting.

To reduce the weight of timber.

Air or natural seasoning: timber stacked in ventilated shady place. Slow process takes six months to two years

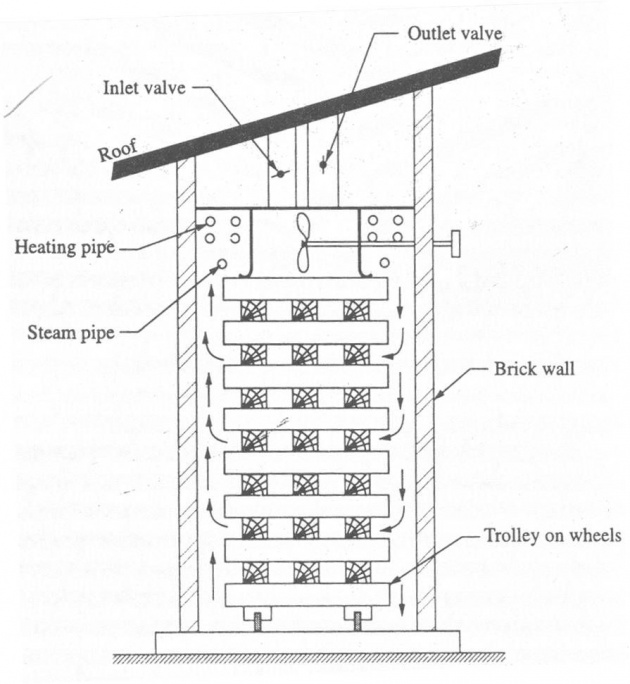

Kiln or artificial seasoning: steam chamber with controllable temperature and humidity. Rapid 4-5 days.

Natural seasoning – air drying

Advantages

Not much attention needed

Simple and cheap method

Less chances of damage to timber

Disadvantages

Very slow process

Considerable space is required

Difficult to get desirable moisture content

Chances of attack by fungi and insects

Benefits of drying

Drying timber increases its:

strength;

stiffness;

stability

durability; &

ease of fastening.

Natural seasoning – water seasoning

Logs of wood are completely immersed in a running stream of water.

Longer ends of logs are kept pointing up-stream.

Sap, sugar and gum etc. are leached out of the wood and replaced by water.

Disadvantage: the process reduces the elasticity and durability of the timber. The timber becomes brittle.

Artificial seasoning

It is quick method, and moisture content can be kept under control (4-12% depending upon conditions).

For dry region the water content may be 4-6 %.

For humid regions the water content may be around 10%.

The most common method of artificial seasoning is kiln seasoning method.

Electrical seasoning:

The logs are placed in such a way that their two ends touch the electrodes. Current is passed , wood resists the flow of current. During this process, heat is generated which results in drying of timber.

Timber preservation

Preservation is protection of timber from attack of insects and internal decay.

Perfect seasoning is the best form of timber preservation.

Methods of preservation

Tarring

Charring

Painting

Creosoting

Ascue treatment

Fire proofing

Tarring: A coat of tar or tar mixed with pitch is applied. Used for rough types of work, such as timber fences, ends of door and window frames (built into the walls).

Charring: to prevent dry rot and insect attacks, the lower ends of posts to be embedded in ground are charred. The posts are charred to depth of 1.5 cm over a wood fire and then quenched in water.

Painting: carried out on the thoroughly seasoned wood other wise paint may confine sap and cause the decay.

Creosoting:

Creosote oil is most widely used preservative treatment where dark color and odour do not make product too objectionable.

It is applied under pressure of 9 bars and at a temp of 50oC.

Creosoting preserves timber from rot and insect attacks.

It is usually employed for piles, poles and railway sleepers.

Ascue treatment: Ascue is in powder form. A solution is prepared by dissolving 6 parts of powder in 100 parts by weight of water. The solution is sprayed on the timber.

Fire proofing: timber made fire resistance by soaking in NH4SO4, NH3Cl, NH4PO3, NaAs, ZnCl.

Preservatives

Oil type preservatives: applied over outside of exposed timber, give un-pleasant smell, timber can not be painted. e.g. cerosote, solignum, carbolinium.

Water soluble preservatives: are odorless organic or inorganic salts as zinc chloride, boric acid etc. These are applied to timber used inside locations only. Preservative used in water 6 part of powder and 100 parts by weight of water.

Solvent treatment: Consist of toxic chemical compounds as pentachlorophenole, bezene-hexa-chloride, dichlorodiphenyl trichloro-ethane (D.D.T) and copper naphathenate. These are dissolved in kerosene, sprit etc.

Acetic anhydride treatment: It is used for veneers, plywood and light lumbers protection against decay by acetylation. They are treated with acetic anhydride vapor, which minimizes swelling and improves resistance to decay and attack by insects.