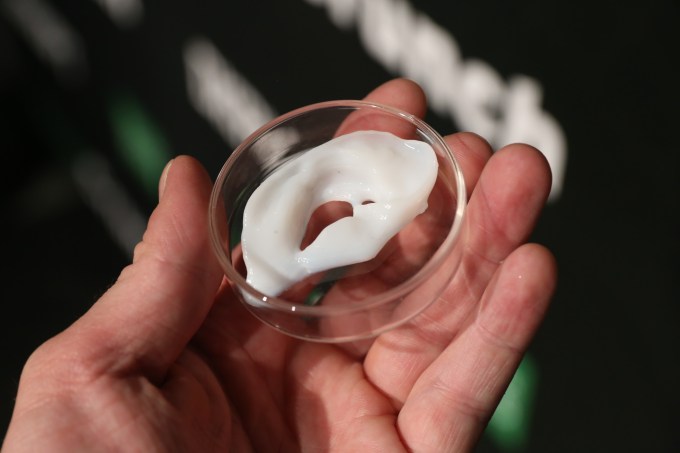

U.S. biotech startup BioBots sits at the intersection between computer science and chemistry. Its debut product, a desktop 3D printer for biomaterials, which was just demoed on stage at TechCrunch Disrupt NY — printing Van Gogh’s ear in replica, no less — combines hardware, software and wetware. It’s the latter area where the core innovation sits, says co-founder Danny Cabrera.

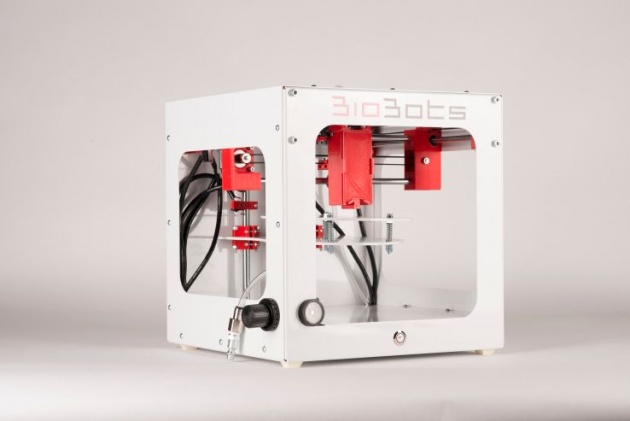

Biofabrication, the process of artificially building living tissue structures, is not a new field — there is more than a decade of research in this area already. But Cabrera and his co-founders believe they have spotted an opportunity to overhaul expensive (circa $100,000+), large, complex legacy devices — taking inspiration from the small, low-cost desktop 3D printers being used by the maker movement to extrude plastic.

Instead of plastic, BioBots’ 3D printer uses a special ink that can be combined with biomaterials and living cells to build 3D living tissue and miniature human organs. The use-case at this point is for research and pre-clinical screening, such as drug testing (as a replacement for animal testing). It’s not about 3D printing replacement organs from a person’s own cells — albeit developments in this area are heading (incrementally) in that direction. More near term future potential for the tech is to help foster bespoke disease therapies, according to Cabrera.

“We really see it as a product for pharmaceutical companies right now, for companies that are doing clinical drug testing,” he tells TechCrunch. “You can use these devices to build 3D living tissue models using human cells, and you can use those models which are way more complex than 2D tissues or animals. They really recapitulate the function of the body. And you can use them to develop compounds for clinical settings. And catch the false positives before they get to clinical trials.”

“Looking down the line for us we see this as a way to develop personalized therapy routines. So you can have patients coming into the clinic and we can take cells directly from the patient and build 3D tissues, miniature tissues, specifically for that patient and test different treatments, different drug routines and personalized therapy’s for patient-specific disease.

“We’ve got this old school notion that we lump diseases together into categories and we give them names but diseases are all different from individual to individual, and our drug development process is sort of outdated — where we develop one drug for millions of people in these expensive clinical trials. Where today we can really use this technology to build one drug for one individual person,” he adds.

The startup began as a dorm-room project as two of the co-founders were at the point of graduating from their computer science and biology degrees at the University of Pennsylvania last June, drawing on their own research interests in genetic engineering and tissue engineering.

“Our idea was we can use the same approaches that were used in the maker movement to build smaller and cheaper devices in biotech,” says Cabrera. “When we looked at what was out there we found devices that existed were huge — they looked like old mainframe computers, they took up entire rooms, they cost half a million dollars and were really difficult to operate. You needed technicians to operate them.”

The team won $5,000 in early capital via a university competition to develop their first prototype. After selling one to a PhD student they decided the idea had legs, and were selected to go through the Dreamit Health accelerator in Philadelphia, pulling in $50,000 via that program last fall. They’ve now been shipping their initial biomaterial printer for a few months, working closely with researchers to keep tuning the initial product (with a price-tag of around $5,000 on the machine for researchers who are helping with BioBots’ own development).

Their recurring business model will be selling different inks used as the base for printing different biomaterials with the printer. Today it’s launching a beta version of a cartilage ink kit (costing $700).

The printer uses visible (blue) light (combined with a compound photoinitiator that’s contained within its ink) to cure biomaterial structures, rather than pressure or UV light as some of the more established devices do. Cabrera says this is more effective for printing living tissue since pressure and UV can both harm living cells, whereas the blue light it’s using does not have a detrimental impact on cells.

To use the device to fabricate a tissue structure, such as a piece of bone, cartilage or liver, a user combines the BioBots’ photoinitiator powder with whatever living cells they want to print, plus binding factors to ensure the cells stick together.

“Our ink is three powders, they would add their fourth powder, which is the binding factor, and they would have to add their cells, mix that up for 5-10 minutes and then put it into the device, have their structure designs on AutoCAD or Solidworks or whatever CAD software they use. Our software would then convert that file to printer instructions,” explains Cabrera.

The BioBots printer has one extruder and uses hydraulic pressure to push the material out of a syringe. Once the biomaterial is in place the printer shines visible blue light to harden the structure. Print time varies, depending on the type of tissue you’re attempting to fabricate, says Cabrera.

“So far our clients are literally working across the spectrum from bone to lung, liver, heart, brain, skin, cartilage using these processes,” he adds.