Hey guys! Today I want to tell you about an interesting machine because in mechanical engineering we mostly talking about machines. So here we go about Lathe Machine which is mostly using in industries for much mechanical, wood, plastics and many other materials operations also. Well, here we will talk about a simple lathe machine…

Definition: A lathe is a machine where our required job rotated around its axis on one hand and tool gets longitudinal feed about its axis.

We can get operations on lathe like cutting, sanding, knurling, deformation, threading, spot facing, drilling, boring, facing, turning and many others. Lathe design is symmetry like pottery wheel where potter man drawn different designs on potter wheel. We can also assemble many attachments to perform various operations. Mostly operations which are drawn on lath are gun barrels, cam shafts, gun shaft, musical instruments etc…

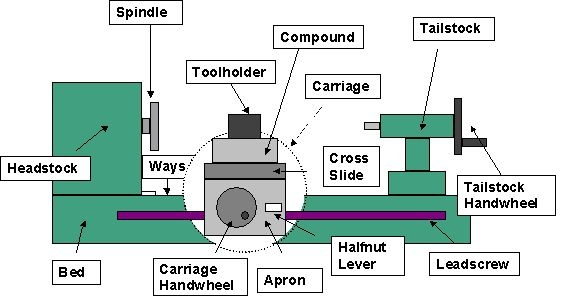

Parts:

Lathe has formally these parts;

Head Stock, Tail Stock, Bed, Carriage, Gears, Compound Rest, Lock Nuts, Lead Screw, Face Plate, Belt Drive etc…

- Head Stock: Head stock consists of all feeding system including different speeding and gear system. It’s called major and important part of lathe. Threading system also in this section. We can change here our threading system into millimeters or inches. We can slow or up our machines speed in this major part. Two or three pulleys also located in this speeding system.

- Tail stock: Tail stock located in the front of head stock. Its gives support our rotating job so that why our required operations will be done safely…..we can also turn here long jobs because tail stock will be support them.

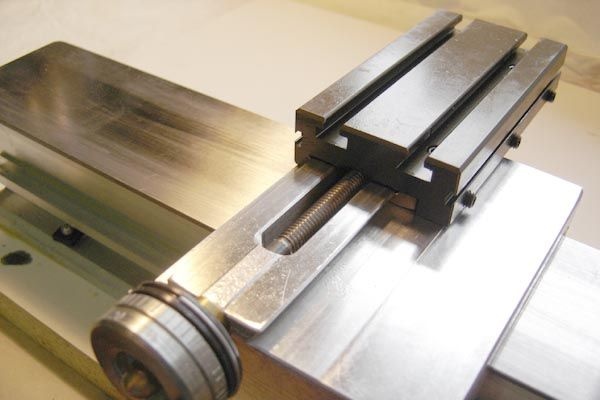

- Carriage: It’s also a big part of lathe because our operational tools also held in this part. We can feed our tool here and can also feed in correct sense, means parallel to machines axis or perpendicular to machines axis. We can change our tools with respect our required operations. Cutting tool for cutting, facing tool for facing, Boring, parting off, threading, and drilling tools for their required operations.

- Bed: bed also important part of lath machine because all weight of machine held on bed. So, if bed strong machine will bear all vibrations which will happen sin any operation.

Writer: Waleed Altaf