One practical medicine when we are hurt, wound plaster. Many of the content contained in the plaster wounds that make the wound to dry quickly after wearing the plaster. In East Java, precisely in the city of Malang, there is one of the largest factories that Elastoplast wound plaster maker. You must be familiar at the product.

Immediately, we peek steps to make plaster wound. The first step, we look at what are the necessary ingredients. There are 13 types of raw materials used, such as pine tree sap that is already congested. At the time of preparing the raw material above, it is recommended to use masks, since at the time of weighing will be a lot of dust scattered, then the virgin in the weighing area is provided a vacuum cleaner to reduce dust in the factory area.

In addition to the pine trees there is also a natural rubber material that first cut and the occasional spray of liquid anti-sticking agent, to prevent sticking. Then crushed with a granulator machine. Further material was taken to the mixing chamber, in this classroom materials - the ingredients are mixed into the tube. Mixing will produce a very vulnerable Solfen Gas burning. Blits camera flashes could spark why, in this area there should be no cell phone lines are lit up.

Meanwhile plaster fabric made of nylon and rayon are also prepared in this classroom, material motives will be rolled up and checked whether the mold is appropriate or not. Glue and cloth that had been prepared earlier will meet in coatting space, this room is still in the danger zone category or flammable because it still contains Gas Soflen. The result of mixing is the glue that will be glued to the plaster cloth. Liquid glue and fabric will be entered into the coating machines with less temperature 129 degrees Celsius. Once out should be immediately cooled to room temperature, result in the form of rolls of fabric that have been sticky.

If the adhesive has been, is now the turn of protective material called Wound Pad wound or wound bearings, these bearings are able to absorb liquid in the wound so it can help healing faster. Wound plaster does not contain the drug, but only wound plaster protects the wound from the outside air that can cause an infection so the antibodies we can heal wounds faster. Wound Pad must be sterile and should not be touched because it has the right cavity so that the wound moist.

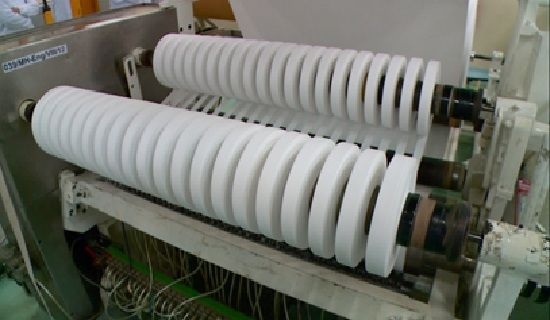

To adjust the size of the plaster, Wound Pad cut by slitting machines. There were cut 25 millimeters, some are 18 and 30 kilometers to stay made into rolls. In 15 minutes, the machine is able to make 40 rolls at a time, stay taped and stamped total length of 200 meter rolls. Sticky roll of fabric that has been called Jumbo Roll. The rolls should be cut into sections with Slitting machines. If it is cut and then unite all ingredients are processed dressings.

In the process of this Dressing ranging from Mother Roll, Wound Pad, Wound Pad protector made from silicon, and cover the plaster together, the machine will rotate all the ingredients and bring together parts of parts. Mother patterned Roll will run through some rell, while Wound Pad will be entered into the machine to cut and paste on Mother Roll. The machine will further put silicone to protect Wound Pad and install front and rear cover. All is rapid, within one minute the machine is capable of producing 1500 plaster ready to use.