Wood products

Veneers Plywood

Fiber Boards

Particle Boards or Chip Boards

Block Boards

Batten Boards

Lamina Boards

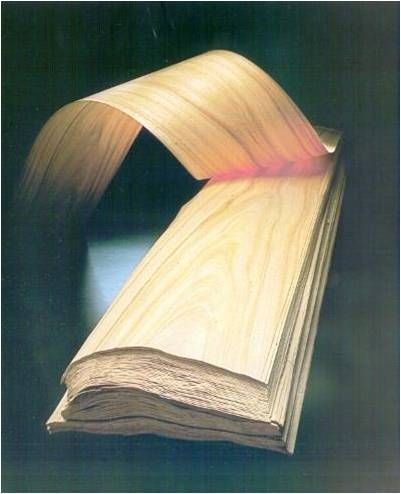

Veneers Thin sheets of wood peeled off, sliced or sawn from a log of wood having attractive or artistic grain arrangement Sheet thickness from 0.4 mm to 6 mm High quality material is used as a decorative finish. Lower grade material is used to make plywood and similar .

Plywood Under pressure gluing together of veneer plies in odd number to make 3 mm to 6 mm thick sheet Grains of alternate layers at right angle to each other Outer plies called face plies or faces

Used for covering or paneling of walls, doors, furniture and shuttering

Plywood Advantages Better appearance Stronger than same thickness wood Elastic and may be bent to give any shape Not much affected by climatic changes Uniform strength in all directions Available in large sizes not possible in wood Almost negligible shrinkage and expansion Does not split under nails Plywood is generally made in two ways Cold pressing T he adhesives are set at room temperature Hot pressing The glued veneers are pressed in large hydraulic presses. The leaves of these presses are electrically heated (150–250 oC)

Lamin board It is a board having a core of strips (7 mm thick) glued together face to face to form a slab which in tern is glued between two or more veneers.The lamin boards are light, strong and do not split or crack easily.Uses: walls, ceilings, partitions and packing cases.

Block board The core consists of smaller timber block up to 25 mm in width.Uses: construction of railway carriages, bus bodies, marine & river crafts, furniture, partitions , panelling, prefabricated houses, etc.

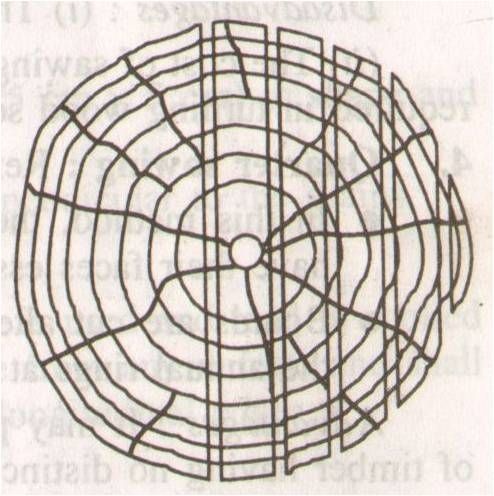

Shrinkage in sawn section

Tangential shrinkage is the highest;Pines have a porous cell structure:They can be dried very quickly.Turn around time from saw to store can be as low as a week.Drying can be very slow.It must be done carefully.

Testing of timber

Some important which are performed to determine the mechanical properties of timber are:

Tensile strength test

Compressive strength test

Shear strength test

Bending strength test

Moisture content

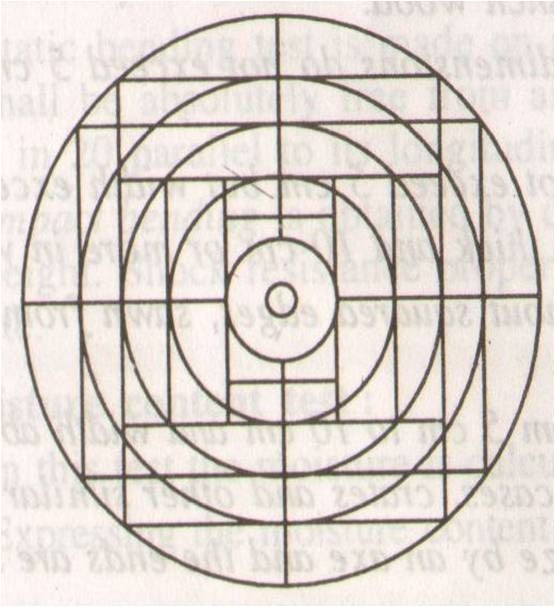

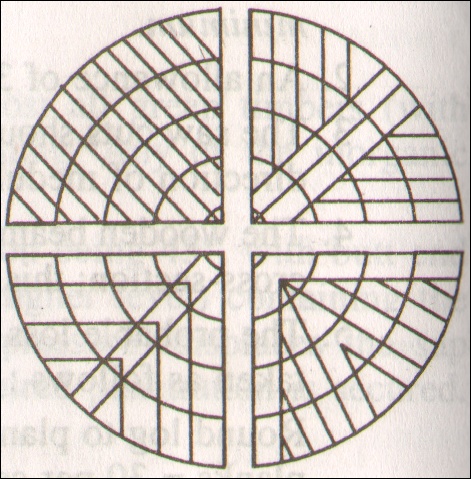

Methods of sawing timber Timber may generally be sawn in one of the following ways:

Ordinary sawing

Tangential sawing

Radial sawing

Quarter sawing

Ordinary sawing

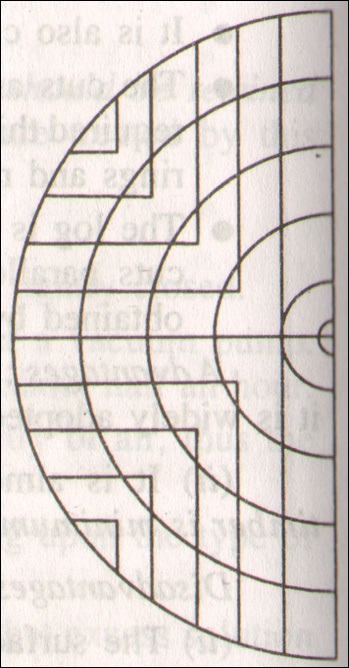

It is also called flat or slab sawing

Advantage: It is very easy and quick method of sawing. It is most economical method and wastage of timber is minimum.Disadvantage: The planks are liable to warp and twist as a result of unequal shrinkage. The surface of plank show varying features

Tangential sawing

The boards or planks are sawn out of the log tangentially to the annular rings.Adopted when annual rings are very distinct and medullary rays are not clearly defined.

Advantage:economical due to less wastage and involves less labour

.Disadvantage: sections obtained are weak and do not suit for heavy work as for floor etc.

Radial sawing

The sawing is done parallel to the medullary rays & perpendicular to annual rings Used for conversion of hard timber.Advantage: The cut section shrinks at uniform rate and warping is therefore less. The wood is used for high quality work It gives wood with decorative effect

Disadvantage: Wastage is higher Cost of sawing is higher and more time is needed in sawing

Quarter sawing

In this method, the log is cut into four quarters. Disadvantage: Tendency to bend in a transverse direction More labour is required and results in more wastage.Log: trunk of tree left after cutting all branches.Baulk: roughly squared swan log.

Batten: timber whose cross-sectional dimensions do not exceed 5 cm in either direction.

Plank: it is the timber whose thickness does not exceed 5 cm but width exceeds 5 cm Board: it is a thin plank under 5 cm thick and 10 cm or more in width

Pole: it is a long, solid, straight timber of a tree 10-30 cm in diameter and gradually tapering.

Post: timber used in upright position in building fencing or other structural work.

Sleeper: piece of timber used as transverse support under rails in railway lines.

Treatment processes

Surface application: also known as brush and spray method. At least two coats are applied. Hot solution of preservative is used if possible. Used for treating material on site. This method is used when naturally resistant timbers are used. Soaking treatment: It is also known as steeping. Seasoned timber is submerged in the preservative for 7-10 days. Used for timber having sapwood, and for light and medium density timber.s: In this process timber is stacked in to the tank and cold preservative is run in to the tank. The preservative is then heated to 95oC Hot and cold proces and maintained for suitable period. After that it is allowed to cool until the required absorption is obtained. A penetration upto 5 cm is obtained.Pressure process: injecting preservative under pressure into the timber is the most effective method of treating timber with preservative.