“Soap is the alkali salt of higher fatty acid”

Detail-

1-Melting of fats.

In this process raw of fat are melted to change in oil.Then this oil is sent to the filtration section.

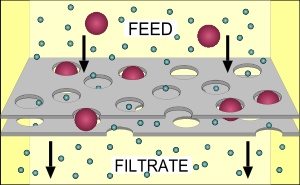

2-Filtration.

In this section oil is filtered.Impure and suspended particles are separated and molten oil is sent to the reaction chamber.

3-kettle process.

In this section about ¼ of the kettle is filled with oil.12% to 15% alkali solution is also added in the chamber.Some heat is also provided to contents with the help of steam coil.It will perform two function,firstly, it will heated the solution .Secondly, it will also agitate the solution. It take place to form soap and glycerine.After complete the process in about 4 to 5 hrs .The soap will present in the main kettle in the form of solution with excess amount of water,glycerine, alkali and small amount of sodium carbonate.A thick layer of soap will form over spent lye which remain in the lower portion of kettle. Soap contents are washed with water to remove excess alkali. Wash water are removed from the bottom of kettle and sent to alkali tank for the preparation of alkali. At the end, soap is collected from the bottom of kettle. Some treatment lower grade soap is sent to the market. Fine grade soap is sent to the next section .

.

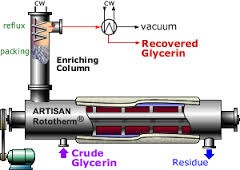

4- Recovery of glycerin.

Spent lye is recovered from the bottom of the kettle and sent to the recovery section to obtain glycerin.

5- Drying.

In this section, fine soap is dried in a vacuum dryer to obtain required water contents. Dry soap is passed through the cutter to make flakes.

6- Mixing.

In this section the color, fragrance and additives are mixed with soap flakes and completely mixed.

7-Bar formation

In this section, soap is converted into a soap bar shape. The bar shape is cut to the required size and stamping and packing it.