Introduction

Electronic measurements are of two kinds

– Those made of electrical quantities such as voltage, current, resistance and capacitance, and

– Those made by electrical or electronic means of non electrical quantities such as pressure, temperature and flow rate.

_____________________________________________________________________________________

Some Definitions

The measurement of a given quantity is essentially an act or the result of comparison between the quantity (whose magnitude is unknown) and a predefined standard. Since the two quantities are compared the result is expressed in numerical values.

In order that the results of the measurement are meaningful, there are two basic requirements:

– The standard used for measurement purposes must be accurately defined and should be commonly accepted, and

– The apparatus used and the method adopted must be provable.

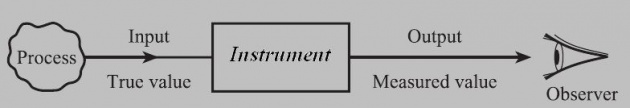

We define a process as a system which generates information. Examples are a chemical reactor, a car and a human heart.

Displacement, velocity and acceleration are information variables generated by a car. A chemical reactor generates temperature and pressure information variables.

The observer is person who needs the information from the process.

The purpose of the instrument is to link the observer to the process.

In an ideal instrument, the measured value would be equal to the true value.

The accuracy of the instrument can be defined as the closeness of the measured value to the true value.

A perfectly accurate instrument is a theoretical ideal and the accuracy of a real instrument is quantified using measurement error, where

Error = measured value – true value

Or

Error = instrument output – instrument input

If the measured value of the rotational speed of an engine is 3140 rpm and the true value is 3133 rpm, then error is 7 rpm.

Error is the main performance indicator for an instrument.

The term tolerance is also used for error.

______________________________________________________________________________

Purpose of Measurement

Measurements are made for one or more of the following functions

– To monitor a process

– To control a process

– To carry out some analysis

Monitoring

Thermometers, barometers, gas and energy meters only indicate certain quantities. Their readings do not perform any control function in the normal sense. These instruments are made for monitoring purposes only.

Control

The thermostat in a refrigerator or geyser determines the temperature of the relevant environment and accordingly switches off or on the cooling or heating mechanism to keep the temperature constant, i.e. to control the temperature. Controlling a variable is rather an involved process and is therefore a subject of study by itself.

Analysis

Measurements are also made to

– Test the validity of predictions from theories

– Build empirical models

– Characterize materials, devices and components

Standards

– Working standards

– Secondary standards

– Primary standards

– International standards

Working standards

– Electrical measurement standards are precise resistors, capacitors, inductors, voltage sources and current sources, which can be used for comparison purposes when measuring electrical quantities.

– For example, resistance can be accurately measured by means of a Wheatstone bridge which uses a standard resistor. Similarly, standard capacitors and inductors can be employed in bridge methods to accurately measure capacitance and inductance.

– The standard resistors, capacitors, and inductors usually found in an electronics laboratory are classified as working standards.

– Working standard resistors are available in values ranging from 0.01 Ω to 1 MΩ, with typical accuracies of ±0.01% to ±0.1%.

– Working standard capacitors are available in values ranging from 0.001 µF to 1 µF, with typical accuracy of ±0.02%.

– Working standard inductors are available in values ranging from 100 µH to 10 H with typical accuracy of ±0.1%.

– Calibrators provide standard voltages and currents for calibrating voltmeters and ammeters.

Secondary standards

– Secondary standards are employed in industry as references for calibrating high accuracy equipment and components and for verifying the accuracy of working standards.

– Secondary standards are periodically checked at the institutions that maintain primary standards.

Primary standards

– Primary standards are maintained at institutions in various countries around the world such as National Bureau of Standards in Washington.

– They are also constructed for the greatest possible accuracy and their main function is checking the accuracy of secondary standards.

International standards

– International standards are defined by international agreements and are maintained at the International Bureau of Weights and Measures in France.

– These are as accurate as it is scientifically possible to achieve.

– They may be used for comparison with primary standards but are otherwise unavailable for any application.

This is all about the Instrumentation and Measurements Chapter one.